ਚੇਨ ਦੀ ਬੁਨਿਆਦੀ ਉਤਪਾਦਨ ਜਾਣਕਾਰੀ ਪੇਸ਼ ਕਰਦੇ ਹਾਂ ਜੋ ਅਕਸਰ ਸਾਨੂੰ ਸੁਣਨ ਨੂੰ ਮਿਲਦੀ ਹੈ। ਉਹ ਲਚਿਲੇ, ਭਰੋਸੇਮੰਦ ਅਤੇ ਲੰਬੇ ਸਮੇਂ ਤੱਕ ਚੱਲਣ ਵਾਲੇ ਹੁੰਦੇ ਹਨ। ਇਸ ਤਰ੍ਹਾਂ ਦੀਆਂ ਚੇਨਾਂ ਕਦੇ-ਕਦੇ ਖੜੇ...">

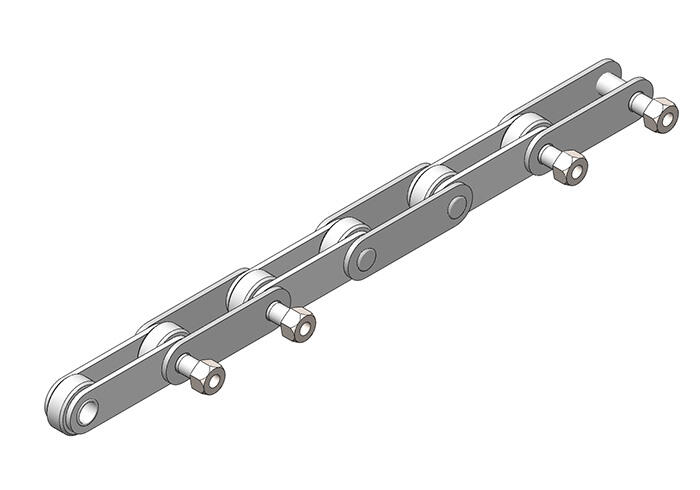

ਹੁਣ ਅਸੀਂ ਮੁੱਖ ਬਣਾਈ ਜਾਂਦੀ ਹੈ ਮਾਹਿਤੀ ਨੂੰ ਪੇਸ਼ ਕਰਦੇ ਹਾਂ ਚੇਨ ਜਿਸ ਬਾਰੇ ਅਸੀਂ ਸਾਨੂੰ ਸਹੀ ਵੇਲੇ ਸੁਨਦੇ ਹਾਂ। ਉਹ ਪ੍ਰਭਾਵਸ਼ਾਲੀ, ਵਿਸ਼ਵਾਸਾਧਾਰੀ ਅਤੇ ਦੀਰਘ ਜੀਵਨ ਦੀ ਹੋਂਦੀਆਂ ਹਨ। ਇਹ ਕਿਹਾ ਗਿਆ ਹੈ, ਇਹ ਚੇਨਾਂ ਕਦੋਂ ਵੀ ਫੈਕਟਰੀਆਂ ਵਿੱਚ ਮਾਸ਼ੀਨਾਂ ਨੂੰ ਉਨ੍ਹਾਂ ਦੀ ਕਾਰਜਤਾ ਨੂੰ ਸਹੀ ਤਰੀਕੇ ਨਾਲ ਕਰਨ ਲਈ ਵਰਤੀਆਂ ਜਾਂਦੀਆਂ ਹਨ। ਇਸ ਲਈ, ਚਲੋ ਸਮਝਣ ਲਈ ਜਾਂਦੇ ਹਾਂ ਕਿ ਕਿਉਂ ਅਲੂਮੀਨੀਅਮ ਰੋਲਰ ਚੇਨਾਂ ਨੂੰ ਮਾਸ਼ੀਨਾਂ ਲਈ ਮੁਲਾਂਕਤ ਹੁੰਦੀਆਂ ਹਨ।

ਅਲੂਮਿਨੀਅਮ ਰੋਲਰ ਚੇਨਾਂ ਦੀ ਘਟੀ ਹੋਈ ਭਾਰ ਵਜਾਏਂਦਰ ਉਨ੍ਹਾਂ ਨੂੰ ਉਨ੍ਹਾਂ ਮਿਸ਼ਨਾਂ ਲਈ ਲੋਕਪ੍ਰੀਤ ਚੋਣ ਬਣਾਉਂਦੀ ਹੈ ਜਿਨ੍ਹਾਂ ਨੂੰ ਉੱਚ ਸਹੀਲਤ ਦੀ ਜ਼ਰੂਰਤ ਹੁੰਦੀ ਹੈ। ਇਹ ਮਤਲਬ ਹੈ ਕਿ ਉਨ੍ਹਾਂ ਨੂੰ ਭਾਰੀ ਚੀਜ਼ਾਂ ਨੂੰ ਉੱਥੇ ਲਿਆ ਜਾ ਸਕਦਾ ਹੈ ਅਤੇ ਕਠਿਨ ਪਰਿਸਥਿਤੀਆਂ ਵਿੱਚ ਕਾਰਜ ਕਰ ਸਕਦੀ ਹੈ ਅਤੇ ਨਹੀਂ ਫੈਲ ਸਕਦੀ। ਇਹ ਗੱਲ ਬਹੁਤ ਜ਼ਰੂਰੀ ਹੈ ਕਿਉਂਕਿ ਮਿਸ਼ਨ ਅਥਾਹ ਕੰਮ ਕਰਦੀਆਂ ਹਨ ਅਤੇ ਖੁਸ਼ਹਾਲੀ ਦੀ ਬਹੁਤ ਸਾਰੀ ਮਾਤ ਸਹਣੀ ਚਾਹੀਦੀ ਹੈ। ਅਲੂਮਿਨੀਅਮ ਰੋਲਰ ਚੇਨਾਂ ਨੂੰ ਵੀ ਬਹੁਤ ਮਜਬੂਤੀ ਹੁੰਦੀ ਹੈ, ਜਿਸ ਵਜ਼ੇ ਉਨ੍ਹਾਂ ਨੂੰ ਉਪਯੋਗ ਵਿੱਚ ਤੋੜ ਜਾਣ ਤੋਂ ਬਚਣ ਲਗਾ ਹੈ।

ਮਾਸ਼ੀਨਾਂ ਵਿੱਚ ਅਲੂਮਿਨੀਅਮ ਰੋਲਰ ਚੇਨ ਦੀਆਂ ਕਈ ਫਾਇਦੇ ਹਨ। ਸਭ ਤੋਂ ਵੱਡਾ ਫਾਇਦਾ ਇਹ ਹੈ ਕਿ ਉਹ ਹੱਲੇ ਹਨ। ਇਹ ਉਹਨਾਂ ਦੀ ਤੁਲਨਾ ਵਿੱਚ ਸਹੁਲਤ ਨਾਲ ਵਰਤੀ ਜਾਂਦੀ ਹੈ ਅਤੇ ਪਹਿਨਦੀ ਹੈ। ਤੁਹਾਡਾ ਫਾਇਦਾ ਇਹ ਹੈ ਕਿ ਕਨਵੇ ਲਾਈਨ ਉਹ ਲੈਵਾਂ ਹਨ, ਜਾਂ ਬਾਕੀ ਕਥਾ ਨਾਲ, ਉਹ ਵੱਖ ਵੱਖ ਤਰੀਕਿਆਂ ਵਿੱਚ ਮਾਸ਼ੀਨਾਂ ਵਿੱਚ ਸ਼ਾਮਲ ਕੀਤੀਆਂ ਜਾ ਸਕਦੀਆਂ ਹਨ। ਇਸ ਸਵੈਂ ਕਰਨ ਦੀ ਕਮਤਾ ਉਹਨਾਂ ਨੂੰ ਵੱਖ ਵੱਖ ਕਾਮ ਦੀਆਂ ਬਣਾਵਟਾਂ ਲਈ ਮੁਠੀਆਂ ਵਿਚ ਵਿਕਲਪ ਬਣਾਉਂਦੀ ਹੈ।

ਮਾਸ਼ੀਨਾਂ ਨੂੰ ਅਲੁਮਿਨੀਅਮ ਰੋਲਰ ਚੇਇਨਾਂ ਦੀ ਵਰਤੋਂ ਕਰਨ ਤੋਂ ਲੰਬੀ ਅवਧੀ ਤक ਸੁਲਭ ਚਲਣ ਅਤੇ ਕਾਰਜਕਤਾ ਪ੍ਰਦਾਨ ਹੁੰਦੀ ਹੈ। ਉਨ੍ਹਾਂ ਨੂੰ ਮਾਸ਼ੀਨਾਂ ਨੂੰ ਵਧੀਆ ਤਰੀਕੇ ਨਾਲ ਅਤੇ ਸਫ਼ਲਤਾਪੂਰਵਕ ਚਲਾਉਣ ਲਈ ਜਾਣਕਾਰੀ ਹੁੰਦੀ ਹੈ। ਮਾਸ਼ੀਨਾਂ ਚੰਗੀ ਤਰ੍ਹਾਂ ਚਲਦੀਆਂ ਰਹਿੰਦੀਆਂ ਹਨ ਜੇ ਉਨ੍ਹਾਂ ਦੀ ਤਰਕੀਬ ਵਿੱਚ ਕੋਈ ਖਰਾਬੀ ਜਾਂ ਮਿਲਾਉਟ ਨਹੀਂ ਹੁੰਦੀ। ਇਹ ਉਨ੍ਹਾਂ ਕਾਰੋਬਾਰਾਂ ਲਈ ਸਮਾਂ ਅਤੇ ਪੈਸੇ ਬਚਾਉਂਦਾ ਹੈ ਜਿਨ੍ਹਾਂ ਨੂੰ ਮਾਸ਼ੀਨਾਂ ਦੀ ਜ਼ਰੂਰਤ ਹੁੰਦੀ ਹੈ ਕਾਰਜ ਕਰਨ ਲਈ। ਅਲੁਮਿਨੀਅਮ ਜਿਵੇਂ ਰੋਲਰ ਚੇਇਨ ਵਰ्षਾਂ ਤक ਵਰਤੀ ਜਾ ਸਕਦੀ ਹੈ ਬਿਨਾ ਕਿਸੇ ਬਦਲਾਅ ਦੀ ਜ਼ਰੂਰਤ ਨਾਲ।

ਅਲੁਮਿਨੀਅਮ ਰੋਲਰ ਚੇਇਨਾਂ ਨੂੰ ਸਹਜ ਤੌਰ 'ਤੇ ਰਸਾਂ ਨਹੀਂ ਪਿਆ ਜਾਂਦਾ, ਜੋ ਇਸ ਦਾ ਪ੍ਰਧਾਨ ਫਾਇਦਾ ਹੈ। ਇਹ ਮਾਨੇ ਜਾਂਦਾ ਹੈ ਕਿ ਉਨ੍ਹਾਂ ਨੂੰ ਗੱਲੀਆਂ ਸਥਾਨਾਂ ਵਿੱਚ ਨੁਕਸਾਨ ਨਹੀਂ ਪਹੁੰਚਦਾ। ਇਹ ਮਾਸ਼ੀਨਾਂ ਨੂੰ ਘੱਟੀਆਂ ਸਥਿਤੀਆਂ ਵਿੱਚ ਕੰਮ ਕਰਨ ਲਈ ਮਹੱਤਵਪੂਰਨ ਹੈ ਜਿੱਥੇ ਉਨ੍ਹਾਂ ਨੂੰ ਗੱਲੀ ਜਾਂ ਰਸਾਂ ਦੀ ਵਰਤੋਂ ਲਈ ਵਰਤਿਆ ਜਾ ਸਕਦਾ ਹੈ। ਉਨ੍ਹਾਂ ਨੂੰ ਸਹਜ ਤੌਰ 'ਤੇ ਰੱਖਰਹਿਸ਼ਤੀ ਵਿੱਚ ਹੈ, ਇਸ ਲਈ ਉਨ੍ਹਾਂ ਨੂੰ ਹੋਰ ਚੇਇਨਾਂ ਤੋਂ ਵੀ ਘੱਟ ਤੇਲ ਜਾਂ ਸੰਗਠਨ ਦੀ ਜ਼ਰੂਰਤ ਹੁੰਦੀ ਹੈ। ਇਹ ਮਾਸ਼ੀਨਾਂ ਨੂੰ ਸੁਲਭ ਚਲਣ ਲਈ ਮਦਦ ਕਰਨ ਲਈ ਹੈ।

ਥੀਕ ਤਰ੍ਹਾਂ ਭਾਰੀ ਬਾਰੀ ਅਲੂਮੀਨੀਅਮ ਰੋਲਰ ਚੇਨਾਂ ਦੀ ਵਰਤੋਂ ਜਲਦੀ ਅਧਿਕਾਰੀ ਲਈ ਉੱਤਮ ਹੁੰਦੀ ਹੈ। ਉਹ ਉੱਚ ਗੱਤੀ ਵਿੱਚ ਕੰਮ ਕਰਨ ਦੀ ਯੋਗ ਹੁੰਦੀ ਹੈ, ਭਾਰੀ ਬਾਰੀ ਲੈ ਸਕਦੀਆਂ ਹਨ, ਅਸਲ ਵਿੱਚ ਬਹੁਤ ਹੀ ਬਹੁਤ ਜਿੰਦਗੀ ਦੇ ਦੌਰਾਨ ਵਰਤੀ ਜਾਂਦੀਆਂ ਹਨ ਕਿ ਪੋਲੀ ਮਾਸ਼ੀਨਾਂ ਵਿੱਚ ਵਰਤੀ ਜਾਂਦੀਆਂ ਹਨ। ਜਲਦੀ ਅਤੇ ਭਾਰੀ ਬਾਰੀ ਵਿੱਚ, ਅਲੂਮੀਨੀਅਮ ਰੋਲਰ ਚੇਨਾਂ ਦੀ ਵਰਤੋਂ ਕੰਪਨੀ ਦੀ ਦਰਜਾਬਦਿ ਨੂੰ ਵਧਾਉਣ ਅਤੇ ਫੈਲੇ ਨੂੰ ਘਟਾਉਣ ਲਈ ਕੀਤੀ ਜਾ ਸਕਦੀ ਹੈ। ਇਸ ਲਈ, ਉਹ ਉਨ ਕੰਪਨੀਆਂ ਲਈ ਇੱਕ ਅਚਹਾ ਵਿਕਲਪ ਹੁੰਦਾ ਹੈ ਜਿੱਥੇ ਮਾਸ਼ੀਨ ਲਈ ਇਸ ਨੂੰ ਸੁਲਭ ਢੰਗ ਤੇ ਕੰਮ ਕਰਨ ਲਈ ਵਰਤਿਆ ਜਾਂਦਾ ਹੈ।

ਖਤਰਨਾਕ ਉਪਕਰਣ ਉਤਪਾਦਨ: ਉਤਪਾਦਨ ਪ੍ਰਕਿਰਿਆ ਵਿੱਚ ਆਧੁਨਿਕ ਉਪਕਰਣ ਦੀ ਵਰਤੋਂ ਕਰਕੇ ਉਤਪਾਦਨ ਦੀ ਉੱਚ ਸਹੀਗਣਾ ਅਤੇ ਉੱਚ ਗੁਣਵਤਾ ਨੂੰ ਯਕੀਨੀ ਬਣਾਉਣਾ, ਉਤਪਾਦਨ ਦੀ ਦਰ ਨੂੰ ਵਧਾਉਣਾ ਅਤੇ ਉਤਪਾਦਨ ਦੀ ਸਹੀਗਣਾ ਨੂੰ ਬਣਾਉਣਾ, ਅਤੇ ਮਾਰਕੇਟ ਦੀ ਤੀਜੀ ਪੈਰਸ਼ਾਨੀ ਵਿੱਚ ਟੈਕਨੋਲੋਜੀ ਦੀ ਫਾਸਲ ਰੱਖਣੀ। ਟੈਕਨੋਲੋਜੀ ਦੀ ਖੋਜ ਅਤੇ ਵਿਕਾਸ ਦੀ ਕਮਤਾ: ਲੰਬੀ ਅਡੀ ਉਦਯੋਗ ਅਨੁਭਵ ਅਤੇ ਜਿਆਦਾ ਤੌਰ ਤੇ ਬਣਾਏ ਗਏ ਉਤਪਾਦਨ ਦੀ ਖੋਜ ਅਤੇ ਵਿਕਾਸ ਦੀ ਕਮਤਾ ਉੱਤੇ ਆਧਾਰਿਤ ਹੈ, ਇਸ ਲਈ ਇਸ ਦੀ ਖੋਜ ਅਤੇ ਵਿਕਾਸ ਦੀ ਟੀਮ ਅਤੇ ਕਮਤਾ ਹੈ। ਇਹ ਸਥਿਰ ਤੌਰ ਤੇ ਉਤਪਾਦਨ ਦੇ ਡਿਜਾਈਨ ਅਤੇ ਉਤਪਾਦਨ ਪ੍ਰਕਿਰਿਆ ਨੂੰ ਵਧਾਉਣ ਲਈ ਸਮਰਥ ਹੈ ਤਾਂ ਕਿ ਉਤਪਾਦਨ ਦੀ ਪੰਜਾਬ ਅਤੇ ਟੈਕਨੋਲੋਜੀ ਲਈ ਨਵੀਂ ਮਾਰਕੇਟ ਮੰਗਾਂ ਨੂੰ ਅਧਾਰ ਦਿੰਦਾ ਹੈ।

ਵਿਸ਼ਿਸ਼ਟ ਉਤਪਾਦ ਪੋਰਟਫੋਲੀਓ: ਵਿਸ਼ਾਲ ਪ੍ਰਕਾਰ ਦੇ ਉਤਪਾਦਾਂ ਦੀ ਖਾਤਰ ਜਿਹੜੇ ਵਿੱਚ ਕਨਵੇਅਰ ਚੇਨ, PTO ਸ਼ਾਫ਼ਟ, ਸਪਰਕੈਟਸ, ਗੀਅਰ, ਕਾਫਲਿੰਗ, V-ਪੁਲੀਆਂ ਅਤੇ ਵੋਰਮ ਗੀਅਰ ਰਿਡিউਸਰ ਸ਼ਾਮਲ ਹਨ। ਇਨ ਉਤਪਾਦਾਂ ਨੂੰ ਚਿੱਨਾ, ਸਿਮੈਂਟ, ਖਾਨਾਬਾਦੀ, ਖਾਣਾ, ਪਾਣੀ, ਕੁੱਲਾ, ਟੋਮੋਬਾਇਲ ਅਤੇ ਪਾਲਮ ਤੌਲ ਜਿਹੜੇ ਇਨਡਸਟਰੀਆਂ ਵਿੱਚ ਵਿਸ਼ਾਲ ਪ੍ਰਯੋਗ ਹੁੰਦਾ ਹੈ ਅਤੇ ਇਨ੍ਹਾਂ ਨੂੰ ਇੱਕ ਸਟੋਪ ਉਤਪਾਦ ਸੰਘਣ ਦੀ ਵਰਤੋਂ ਕਰਨ ਲਈ ਦੇਣਗੇ। ਉੱਚ ਗੁਣਵਤਾ ਦੀ ਗਾਰੰਟੀ: ਉਤਪਾਦਨ ਪ੍ਰਕਿਰਿਆ ਵਿੱਚ ਆ代ਨ ਸਮਰਥ ਉਤਪਾਦਨ ਸਮਰਥਾਂ ਅਤੇ ਕਠੋਰ ਗੁਣਵਤਾ ਨਿਯੰਤਰਣ ਉਪਾਯਾਂ ਦੀ ਵਰਤੋਂ ਕੀਤੀ ਜਾਂਦੀ ਹੈ। ਇਹ ਗੁਣਵਤਾ ਅਤੇ ਵਿਸ਼ਵਾਸਾਧਾਰਾ ਦੀ ਸਥਿਰਤਾ ਨੂੰ ਸਹੀ ਕਰਦਾ ਹੈ, ਗੰਰਾਂ ਦੀ ਫੈਲੇ ਅਤੇ ਮੈਂਟੇਨੈਂਸ ਖ਼ਰਚ ਘਟਾਉਂਦਾ ਹੈ ਅਤੇ ਉਤਪਾਦਨ ਦਰ ਨੂੰ ਵਧਾਉਂਦਾ ਹੈ।

ਵਿਸ਼ਾਲ ਉਦਯੋਗ ਅਨੁਭਵ: 2005 ਵਿੱਚ ਸਥਾਪਿਤ ਹੋਣ ਤੋਂ ਬਾਅਦ, ਜਿਸ ਦੀ ਕਾਰਖਾਨੇ 2000 ਤੱਕ ਵਾਪਸ ਜਾਂਦੇ ਹਨ, ਇਸ ਕਨਮਪਨੀ ਨੂੰ ਵੱਖ-ਵੱਖ ਮਾਈਡਸ਼ ਜਿਨਾਂ ਗਿਆਰਬਾਕਸ, ਸ਼ੇਨਜ਼, ਟ੍ਰਾਂਸਮਿਸ਼ਨ ਸ਼ਾਫਟਾਂ ਅਤੇ ਟ੍ਰਾਂਸਮਿਸ਼ਨ ਲਾਈਨ ਪਾਰਟਸ ਵਿੱਚ ਵਧੀਆ ਨਿਰਮਾਣ ਵਿਸ਼ਾਰਦੀ ਹੈ। ਇਹ ਉਸ ਨੂੰ ਗਹਿਰ ਉਦਯੋਗ ਪ੍ਰਤੀਨਿਧਿਤਾ ਅਤੇ ਵਿਸ਼ਾਲ ਉਤਪਾਦਨ ਅਤੇ ਬਾਜ਼ਾਰ ਚੌਨਾਂ ਨੂੰ ਸਫ਼ਲ ਤਰੀਕੇ ਨਾਲ ਹੱਲ ਕਰਨ ਦੀ ਕਮਤਾ ਦਿੰਦੀ ਹੈ। ਵਿਸ਼ੇਸ਼ ਆਰਡਰ ਮਾਈਡ ਉਤਪਾਦਨ ਦੀ ਕਮਤਾ: ਸਾਡੇ ਕਨਮਪਨੀ ਨੇ ਸਾਡੇ ਗ੍ਰਾਹਕਾਂ ਦੀਆਂ ਵਿਸ਼ਿਸ਼ਟ ਮੰਗਾਂ ਨੂੰ ਸੰਭਾਲਣ ਲਈ ਵਿਸ਼ੇਸ਼ ਆਰਡਰ ਮਾਈਡ ਉਤਪਾਦਨ ਦੀ ਵਿਕਾਸ ਕੀਤੀ ਹੈ ਜੋ ਬਾਜ਼ਾਰ ਦੀਆਂ ਵਿਸ਼ਿਸ਼ਟ ਮੰਗਾਂ ਨੂੰ ਪੂਰਾ ਕਰਦੀ ਹੈ। ਇਹ ਬਾਜ਼ਾਰ ਦੀ ਪੈਰਸਪਟਿਵ ਵਿੱਚ ਵਧੀਆ ਲਿਖਾਵਟ ਅਤੇ ਸਹਿਯੋਗ ਦਿੰਦੀ ਹੈ। ਉਤੱਕ ਅੰਤਰਰਾਸ਼ਟਰੀ ਖਾਤਰੀ: ਗ੍ਰਾਹਕਾਂ ਦੀ ਸਹੀ ਸਹਿਯੋਗੀ ਰਹਿਣ ਤੇ, ਆਰਡਰਾਂ ਲਈ ਜ਼ਿਮਦਾਰੀ ਅਤੇ ਬਾਹਰੀ ਗ੍ਰਾਹਕਾਂ ਨਾਲ ਲੰਬੀ ਅਤੇ ਸਥਾਈ ਸਹਿਯੋਗ ਦੀ ਵਿਕਾਸ ਕਰਨ ਤੇ ਇਸ ਕਨਮਪਨੀ ਦੀਆਂ ਉਤਪਾਦਨ ਯੂਰਪੀ ਬਾਜ਼ਾਰ ਵਿੱਚ ਵਧੀਆ ਲੋਕਪ੍ਰੀਤੀ ਹੈ। ਇਹ ਦੁਨੀਆ ਭਰ ਵਿੱਚ ਗ੍ਰਾਹਕਾਂ ਦੀ ਵਿਸ਼ਵਾਸ ਜਿੰਦਾ ਕਰ ਸਕਦੀ ਹੈ ਅਤੇ ਇਸ ਦੀ ਬ੍ਰਾਂਡ ਪ੍ਰਭਾਵਕਾਰੀਤਾ ਲਗਾਤਾਰ ਵਧ ਰਹੀ ਹੈ।

ਗੁਣਵੱਤਾ ਬਾਅਦ-ਸੇਲਜ਼ ਸਪਰਸ਼: ਬਾਅਦ-ਸੇਲਜ਼ ਸਰਵਿਸ ਲਈ ਇੱਕ ਪ੍ਰੋਫੈਸ਼ਨਲ ਇੰਜ਼ੀਨੀਅਰ ਟੀਮ ਧਰਾਵਨ ਤੋਂ, ਇਹ ਉਤਪਾਦ ਵਰਤੋਂ ਦੌਰਾਨ ਮਿਲਣ ਵਾਲੀਆਂ ਸਮੱਸਿਆਵਾਂ ਨੂੰ ਜਲਦੀ ਹੱਲ ਕਰ ਸਕਦਾ ਹੈ, ਗ੍ਰਾਹਕਾਂ ਨੂੰ ਤਕਨੀਕੀ ਸਮਰਥਨ ਅਤੇ ਹੱਲ ਪ੍ਰਦਾਨ ਕਰਦਾ ਹੈ, ਉਤਪਾਦਨ ਦੀ ਜਾਰੀ ਰੱਖਣ ਲਈ ਯਕੀਨ ਪੈਦਾ ਕਰਦਾ ਹੈ, ਅਤੇ ਗ੍ਰਾਹਕਾਂ ਨੂੰ ਕੰਪਨੀ ਦੇ ਉਤਪਾਦਾਂ ਦੀ ਵਰਤੋਂ ਵਿੱਚ ਯਕੀਨ ਵਧਾਉਂਦਾ ਹੈ। ਸੰਬੰਧਿਤ ਜਾਣਕਾਰੀ ਦਾ ਭਰਪੂਰ ਪ੍ਰਦਾਨ: ਸਾਡੇ ਪਾਸ ਸਾਡੇ ਸਹਿਯੋਗੀ ਅਤੇ ਬਲੋਗ ਖੰਡ ਹੈ, ਜੋ ਉਦਾਰ ਜਾਣਕਾਰੀ ਅਤੇ ਸਵਾਲਾਂ ਦੀ ਜਵਾਬ ਸਾਂਝਾ ਕਰਦਾ ਹੈ, ਜਿਵੇਂ ਕਿ ਚੇਨ ਦੀ ਰਸਤ ਸਮੱਸਿਆਵਾਂ, ਕਾਰਵਾਈ ਲਈ ਸਾਧਾਰਣ ਸਮੱਸਿਆਵਾਂ ਅਤੇ ਹੱਲ, ਚੇਨ ਦੀ ਗੁਣਵੱਤਾ ਨੂੰ ਜਞਾਨ ਦੀ ਵਿਧੀਆਂ ਅਤੇ ਗਿਆਰ ਦੀ ਦੰਤ ਸੰਖਿਆ ਦੇ ਡਿਜ਼ਾਈਨ ਲਈ ਸਹੀ ਤਰੀਕਾ। ਇਹ ਗ੍ਰਾਹਕਾਂ ਨੂੰ ਮੌਲਿਕ ਤਕਨੀਕੀ ਜਾਣਕਾਰੀ ਅਤੇ ਖਰੀਦ ਦੀ ਦਿਸ਼ਾਨਾ ਪ੍ਰਦਾਨ ਕਰਦਾ ਹੈ, ਉਨ੍ਹਾਂ ਨੂੰ ਉਤਪਾਦਾਂ ਅਤੇ ਉਦਾਰ ਟ੍ਰੈਂਡ ਬਾਰੇ ਵੀ ਵਧੇਰੇ ਜਾਣਨ ਦੀ ਮਦਦ ਕਰਦਾ ਹੈ, ਅਤੇ ਕੰਪਨੀ ਦੀ ਪ੍ਰੋਫੈਸ਼ਨਲਟੀ ਅਤੇ ਉਦਾਰ ਵਿੱਚ ਗ੍ਰਾਹਕਾਂ ਲਈ ਦੇਖਭਾਲ ਦਾ ਪ੍ਰਤੀਨਿਧਿਤਵ ਕਰਦਾ ਹੈ।

ਕੋਪੀਰਾਈਟ © ਹੈਂਗਜ਼ਹੌ ਓਸੀਏਨ ਇੰਡਸਟ੍ਰੀ ਕੋ., ਲਿਮਿਟਡ. ਸਭ ਅਧਿਕਾਰ ਰਿਝਰਵਡ